ASCO Homepage

-

pdf version

ASCO (ASCO A SPICE Circuit Optimizer)

Written by João Ramos

Companion to version 0.4.11

Permission is granted to copy, distribute and/or modify this document under the terms of the GNU Free Documentation License, Version 1.2 or any later version published by the Free Software Foundation; with no Invariant Sections, with no Front-Cover Texts, and with no Back-Cover Texts.

ASCO (A SPICE Circuit Optimizer)

Copyright (C) 2004-2022 João Ramos

This program is free software; you can redistribute it and/or modify

it under the terms of the GNU General Public License as published by

the Free Software Foundation version 2 of the License.

This program is distributed in the hope that it will be useful,

but WITHOUT ANY WARRANTY; without even the implied warranty of

MERCHANTABILITY or FITNESS FOR A PARTICULAR PURPOSE. See the

GNU General Public License for more details.

You should have received a copy of the GNU General Public License

along with this program; if not, write to the Free Software

Foundation, Inc., 51 Franklin St, Fifth Floor, Boston, MA 02110-1301 USA

The information described in this manual assumes that is to be used by an expert circuit designer with the knowledge of the operation of a SPICE simulator. The ASCO tool is intended as a helper to the designer in their quest to “better” design a circuit. It shall not be used as an automatic way to size a circuit by someone which cannot understand the consequences of each one of the assumptions made during the optimization.

ASCO tool does not create nor suggest new circuit arrangements, but simplifies the design process, since fine-tuning, verification and optimization of circuit functionality over process-voltage-temperature corners is automated.

ASCO tool can be seen as the automaton that does the tedious work, thus giving time to the designer to concentrate on intellectual challenges of devising new architectures and solutions for existing problems.

This document uses the following conventions for fonts and commands, which are shown in Table 1.1.

Table 1.1:

| Convention |

Description |

|

| courier |

Indicates a code fragment |

|

| Brackets ([ ]) |

Indicates the component is optional |

|

| Arrows (< >) |

Indicates the component is mandatory |

|

| Pipe (|) |

Indicates that one of the items can be selected |

|

All products mentioned in this document are the property of their respective owners and carry the appropriate trademarks, registered trademarks, and/or copyrights. Any trademark infringements are unintentional.

Quick Start Guide

This Chapter describes the minimum set of commands and information needed to start using ASCO to optimize a CMOS inverter with a 10 pF load operating at 850 MHz. The goal is to find the PMOS transistor width for minimum power consumption.

Download the latest version and compile ASCO by typing at the command prompt

tar -zxvf ASCO-<version>.tar.gz

cd ASCO-<version>

make

Copy the executable asco to examples/<YOUR_SIMULATOR>/inv. If you are using EldoTM execute the following commands

cp asco examples/Eldo/inv

cd examples/Eldo/inv

./asco -eldo inv

otherwise, replace the word Eldo and eldo by the appropriate text representing your simulator.

Depending on your computer the optimization can take up to a few minutes. At the end, two log files are available: asco.log which has a summary of the optimization evolution and <hostname>.log where the input and output variables of every SPICE simulation call are stored.

With the data in the following file, it is possible to know the number of SPICE calls (nfeval), the minimum cost (cmin, lower the better) which is a measure on how good the circuit is, and the cost-variance which is an indication of the optimization convergence. The best test vector (best[0]), scaled from -10 to +10 is produced. In addition, a summary of the Differential Evolution optimization algorithm parameters are printed for future reference. In the last lines, the reason for ending the optimization is given.

nfeval=20 cmin=3.1914 cost-variance=3.9852

nfeval=30 cmin=3.1914 cost-variance=2.6059

nfeval=40 cmin=3.188 cost-variance=1.1017

nfeval=50 cmin=3.188 cost-variance=0.11595

nfeval=60 cmin=3.188 cost-variance=0.048998

nfeval=70 cmin=3.188 cost-variance=0.036212

nfeval=80 cmin=3.1879 cost-variance=0.0048361

nfeval=90 cmin=3.1879 cost-variance=0.0025139

nfeval=100 cmin=3.1879 cost-variance=0.00048362

nfeval=110 cmin=3.1795 cost-variance=0.00041958

nfeval=120 cmin=3.1696 cost-variance=0.00012673

nfeval=130 cmin=3.1696 cost-variance=5.568e-05

nfeval=140 cmin=3.1696 cost-variance=1.873e-05

nfeval=150 cmin=3.1696 cost-variance=1.1294e-05

nfeval=160 cmin=3.1696 cost-variance=5.8484e-06

nfeval=170 cmin=3.1696 cost-variance=3.3654e-06

nfeval=180 cmin=3.1696 cost-variance=3.5067e-07

Best-so-far obj. funct. value = 3.1696

best[0]=-7.990420912

Generation=18 NFEs=180 Strategy: DE/rand-to-best/1/exp

NP=10 F=0.5 CR=1 cost-variance=3.5067e-07

INFO: de36.c - Minimum cost variance reached (cvarmin=1.000000E-06)

INFO: Ending optimization

All simulation calls are stored in this file having the name of the running machine. The data is saved in plain text format and allows further post-processing with a spreadsheet or a graphic plotting program. The last line of this file is now shown

+cost:3.169600E+00: P_SUPPLY:3.169600E-01: +VHIGH:2.154500E+00: //

+VLOW:2.605600E-02: WP:1.904311E-03:

The plus signal as the first character in the line, as opposed to -cost, is an indication that all optimization constraints have been met. In the last column, the transistor size, 1.904 mm, that originates the minimum power consumption is presented.

Please keep on reading. Should doubts arise, contact the developer.

Introduction

ASCO aims to bring circuit optimization capabilities to existing SPICE simulators. It takes an unsized netlist and design criteria and outputs a sized netlist. As a result of the previous sentence, the ASCO tool requires an experienced designer who selects the circuit topology, finds reasonable operating conditions with realistic design goals, defines the test benches and measurements for achieving the desired design objectives, evaluates the proposed sized circuits and select the most suitable circuit. All this is based on knowledge of the application. In return, the tool automates the test of multiple candidates for a given fixed circuit using a hybrid optimization strategy with a high-performance differential evolution (DE) global optimization algorithm [SP95] coupled with a local optimizer (Hooke&Jeeves or Nelder-Mead). The best result is passed from one to the next. Different circuit architectures can be tried, falling to the designer the task of selecting the most appropriate one.

The ASCO tool as been written from the ground-up with the purpose of being simulator independent. As long as the simulator reads its inputs from text files, outputs its results in ASCII format, and can be launched from the command line, it can most likely be added to the list of supported SPICE simulators. Even though it has been designed to work with existing SPICE simulators, at this moment it is flexible enough to interact with other tools, for example, with FastHenry.

Today, it is possible to find various offers of commercial products with similar characteristics. In some cases, the optimization algorithms are suitable only for local optimizations. In other cases, they are better than the ASCO tool, but this comes at a monetary cost. Once again, it is up to the designer to decide the best option to meet the design goals.

ASCO is the result of academic research which in itself did not intend to create a new tool, but only to design high performance analog low-power low-voltage circuits for mobile communications. Interaction with other experienced designers has resulted in the ideas existing in the ASCO tool. With the exception of the optimizers, all code has been personally written. The key features of the ASCO tool are:

- Simulator independent: currently out-of-the-box support for EldoTM, HSPICE

, LTspiceTM, Spectre

, LTspiceTM, Spectre , Qucs and ngspice exist. More are to be included in future releases.

, Qucs and ngspice exist. More are to be included in future releases.

- Number of variables: there is, in theory, no limit to the number of circuit variables that can be optimized, except those constraints imposed by the available computer memory and/or the time required to generate a functional circuit. It is currently hardcoded in the C code.

- PVT corners: by using the simulator functionality, the possibility to test various design corners and Monte Carlo analysis is only limited to the simulator capability and by the time it takes to finish the optimization.

- Efficiency: the optimization algorithm features a global optimization using differential evolution. It has been used on a variety of applications and is known to produce good results in an acceptable time. Furthermore, this algorithm can be chained with a local optimizer to gain convergence speed as suggested by open literature.

- Parallel/distributed computation: time savings are achieved by simultaneously evaluating the proposed values over multiple computers on the network. No limit exists on the total number that can be used concurrently.

- Within the supported SPICE simulators, an arbitrary netlist can be optimized on different conditions without having to recompile the code.

- File format: all outputted data and log information is stored in plain text format. This guarantees that they will always be readable in the future. In addition, it makes possible the use of other existing tools to post-process the optimization results.

- It is free software: the code is available under the GNU GPL license.

ASCO has been designed to address problems that are oriented to electric circuits. Although not limited, some possible applications can include:

- Fully redesign a new circuit described in a SPICE netlist.

- Reuse, optimize an existing circuit.

- Migrate an existing and working design to a more advanced semiconductor technology process effortlessly.

- Increase the robustness and yield of an already designed circuit by guaranteeing that it comply with all design goals and constraints in some/all process corners at will.

- Easily explore a new operating point (design space) of an already existing topology, to reduce power consumption, area or both.

- Look for a feasible new design topology before investing a considerable time trying to derive equations that describe its operation.

Refer to Chapter 6 for ready to use practical examples to introduce you to ASCO, a SPICE circuit optimization tool.

ASCO is written in ANSI C. Portability on *NIX type operating systems should follow relatively easily. Download the latest version and at the command line type the following:

tar -zxvf ASCO-<version>.tar.gz

cd ASCO-<version>

make

Two executables are created: asco and asco-test. Copy them to a common directory so that they can be used later.

For portability building and installing across different environments, the use of GNU Autotools is desirable. The necessary configure.ac and Makefile.am files are packed in Autotools.tar.gz distributed alongside with ASCO. Execute

tar -zxvf Autotools.tar.gz

to extract all necessary files. Then, type the following lines to configure and compile

aclocal

automake -f -c -a

sh autogen.sh

./configure

make

and obtain the same executables.

ASCO has been patched to compile natively in win32 using cygwin and MinGW32. However, should difficulties continue, try using Makefile.win32 instead. You are kindly invited to report progress and difficulties.

A binary version is also made available to download at the project homepage, for situations where a build system is not installed.

Before using the example files, the end-of-file format must be converted. This is necessary because ASCO is developed in a *NIX system, where the EOF is 0x0D instead of 0x0D0A.

For increased flexibility but also because sometimes SPICE simulators differ considerably, ASCO flow is sometimes defined at compile time.

Currently, one global (DE) optimization algorithm and two local (Hooke&Jeeves or Nelder-Mead) optimizers are available to use in ASCO. The parameters for tuning the differential evolution (DE) algorithm are accessible via the configuration file. On the contrary, local optimizers can only be tunned in the source code. Furthermore, the selection of the two local optimizers, is only possible at compilation time by editing the file asco.c around Step4.

The local optimizers use an intrinsically a sequential method. To gain design speed in situations where a good local starting point is known, the parallel global DE algorithm can be used in an emulated local mode. Thus benefiting from distributed computing while strongly limiting the search space.

At the present time, three parallelization methods are supported in ASCO. By default, scattering with load balance is used if the source file de36.c is not edited and line: #define MPI_METHOD 3 is not changed to one of the possible methods:

- Send: each process receives one vector at a time and returns the single cost back to the Master process before receiving new parameters (one vector).

- Scatter: within the same generation, all vectors are scattered among all existing processes. All evaluations are performed before returning all the cost values back to the Master process. In the next generation, it repeats itself.

- Scatter with load balancing: for situations where the computer power is evenly available to each one of the processes, either due to different machines or to machines with different loads, balancing the number of simulations according to the computational resources, decreases optimization time. On a perfect balanced situation, all processes start and finish their work at the same time. This, despite having received a different number of vectors.

It is not possible to know on before hand which BSIM transistor model level is going to be needed or has been used in Spectre . The output from Spectre

. The output from Spectre version changes from version-to-version but the change is more significant between different transistor models. As such, the selection between BSIM3 and BSIM4 (the only two supported models) has to be made by editing the source files. Search for BSIM4 string. File auxfunc_measurefromlis.c requires 2 one byte changes, while the file auxfunc_updatelis.c requires commenting 5 lines and un-commenting another 5 lines of code. The changes are self explanatory for an experienced C programmer.

version changes from version-to-version but the change is more significant between different transistor models. As such, the selection between BSIM3 and BSIM4 (the only two supported models) has to be made by editing the source files. Search for BSIM4 string. File auxfunc_measurefromlis.c requires 2 one byte changes, while the file auxfunc_updatelis.c requires commenting 5 lines and un-commenting another 5 lines of code. The changes are self explanatory for an experienced C programmer.

Usage of ASCO requires the existence of a determined number of files that must reside in the current directory. The simulator that evaluates the cost function (see sub-section 4.2.2) must be on the search path.

The definition of the cost function is calculated automatically by the ASCO tool. This is the function that has to be minimized. Individual minimization or maximization of each one of the measurements is also accomplished without user intervention. In most of the cases, only the specification of the parameters range and constraints is sufficient before starting a new optimization.

TODO: A description on the program interface between ASCO and the SPICE simulation program is to be included here.

Figure 4.1:

Interface between ASCO tool and the SPICE simulation program.

|

The Cost Function

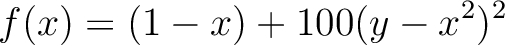

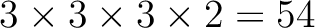

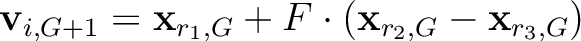

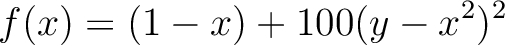

The implemented sizing methodology is a simulation-based optimization approach using a differential evolution optimization algorithm [Sto96] (the global optimizer block in Fig. 4.1). The key property of this optimization algorithm is that it generates new parameter vectors by adding the weighted difference vector between two population members to a third member. If the resulting vector yields a lower objective function value than a predetermined population member, the newly generated vector replaces the vector with which it is compared. For each vector

of generation

of generation  , a perturbed vector

, a perturbed vector

is generated as follows:

is generated as follows:

(4.1)

(4.1)

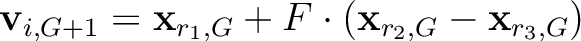

The indexes  ,

,  and

and  indicate three randomly chosen individuals of the population. They are mutually different integer indexes (

indicate three randomly chosen individuals of the population. They are mutually different integer indexes (

![$\in [0, (N-1)]$](img15.png) ) and also differ from the running index

) and also differ from the running index  . The (real) constant factor

. The (real) constant factor  (

(![$\in [0,2]$](img18.png) ) controls the amplification of the differential variation. The vector

) controls the amplification of the differential variation. The vector

that is being perturbed has no relation to the vector

that is being perturbed has no relation to the vector

that will potentially be replaced. To increase the potential diversity of the perturbed parameter vectors, crossover is introduced. More information about the algorithm and details of several variants or strategies for constructing new parameter vectors can be found in [SP95,Sto96]. In addition, this algorithm has been altered to include parameter bounding, stop criteria and mixed continuous/discrete parameter support.

that will potentially be replaced. To increase the potential diversity of the perturbed parameter vectors, crossover is introduced. More information about the algorithm and details of several variants or strategies for constructing new parameter vectors can be found in [SP95,Sto96]. In addition, this algorithm has been altered to include parameter bounding, stop criteria and mixed continuous/discrete parameter support.

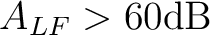

Any circuit variable (device sizes, component values, bias inputs, ...) can be selected as optimization parameters. Furthermore, one or more optimization objectives (minimize, maximize) can be specified as well as a number of (performance) constraints (e.g.

or

or

). All these requirements (

). All these requirements ( objectives and

objectives and  constraints) are combined into a single cost function 4.1 which can be evaluated by the optimizer:

constraints) are combined into a single cost function 4.1 which can be evaluated by the optimizer:

with  and

and  the weights for the cost due to the objectives and constraints, respectively, and where

the weights for the cost due to the objectives and constraints, respectively, and where  indicates performances, either simulated or specified. With properly scaled weights (which is very easily accomplished), the optimizer will first try to find feasible solutions (satisfying the constraints) and then further tunes the parameters to optimize the objectives. This scaling can easily be adjusted manually after a “dry-run” (which can also be automated) and only requires altering the order of magnitude of one of the weights depending on the cost values which are logged. In order to deal with complex problems with many constraints, a minimax problem formulation is used in (4.2). When the genetic algorithm proposes bad combinations of parameters (e.g. out of bound), a “high” cost is assigned (e.g.

indicates performances, either simulated or specified. With properly scaled weights (which is very easily accomplished), the optimizer will first try to find feasible solutions (satisfying the constraints) and then further tunes the parameters to optimize the objectives. This scaling can easily be adjusted manually after a “dry-run” (which can also be automated) and only requires altering the order of magnitude of one of the weights depending on the cost values which are logged. In order to deal with complex problems with many constraints, a minimax problem formulation is used in (4.2). When the genetic algorithm proposes bad combinations of parameters (e.g. out of bound), a “high” cost is assigned (e.g.  ) to such solutions.

) to such solutions.

In order to facilitate the automated optimization of specific circuit classes (Op-Amps, comparators, ...), constraint and objective templates can be loaded. These could have been stored for reuse by the designer himself or provided by another expert designer.

Stop Criteria

Allows halting the optimization under user-defined conditions. Currently defined as the maximum number of generations that has been reached or the minimum cost variance is satisfied. See sub-section 4.3.2/Differential Evolution Options for further details.

A set of files are required to define the netlist and optimization configuration. First, a brief enumeration is given which is followed by a more in-depth description of each one of the files. They are:

| <inputfile>.* |

Properly formatted SPICE input netlist. Default extension is .cir for EldoTM, .sp for HSPICE , .net for LTspiceTM, .scs for Spectre , .net for LTspiceTM, .scs for Spectre , .txt for Qucs and .sp for ngspice. , .txt for Qucs and .sp for ngspice. |

| <inputfile>.cfg |

Configuration file having the same name as the SPICE input netlist with .cfg extension. |

| extract/ |

Extract commands for each one of the performances are stored in this directory. |

Upon starting an optimization, the following files are created.

| <hostname>.tmp |

Temporary file containing a post-processed version of the SPICE input netlist <inputfile>.*. |

| <hostname>.log |

Simulator results log file. |

| <hostname>.* |

Simulator specific input/output files. |

| asco.log |

Optimizer log file. |

In the SPICE input netlist, all devices, sub-circuits, and simulation commands necessary to have a functional simulation must exist. The measurement lines are better excluded from this netlist and should be introduced via the configuration file (<inputfile>.cfg) for flexibility. An example for a simple CMOS inverter in EldoTM is now shown:

*Digital inverter

.PARAM V_SUPPLY = '#V_SUPPLY#'

.PARAM INP_FREQ = '#INP_FREQ#'

.PARAM INP_PERIOD = '1/INP_FREQ'

.PARAM NO_PERIODS = '4'

.PARAM TMEAS_START = '(NO_PERIODS-1)*INP_PERIOD'

.PARAM TMEAS_STOP = '(NO_PERIODS)*INP_PERIOD'

.PARAM TMEAS_1 = 'TMEAS_STOP -3*INP_PERIOD/4'

.PARAM TMEAS_2 = 'TMEAS_STOP -1*INP_PERIOD/4'

*** *** SUPPLY VOLTAGES *** ***

VDD VDD 0 V_SUPPLY

VSS VSS 0 0

*** *** INPUT SIGNAL *** ***

VSIG IN VSS PULSE V_SUPPLY 0 'INP_PERIOD/2' 'INP_PERIOD/1000'

+ 'INP_PERIOD/1000' 'INP_PERIOD/2' 'INP_PERIOD'

*** *** CIRCUIT *** ***

MP OUT IN VDD VDD PMOS W='#WP#' L=#LMIN#

MN OUT IN VSS VSS NMOS W='#WP#/3' L=#LMIN#

CL OUT VSS 10p

*** *** ANALYSIS *** ***

.TRAN 'INP_PERIOD/1000' 'NO_PERIODS*INP_PERIOD'

.MC 2 ALL

.PROBE TRAN V(IN)

.PROBE TRAN V(OUT)

.OPTION EPS=1E-6

.INCLUDE p.typ

.INCLUDE n.typ

.END

In the above netlist representing a digital inverter, all lines are the same as in a normal simulation with a couple of exceptions:

- All values that are to be replace by the optimizer are enclosed in number sign # #. This does not necessarily imply a variable to optimize. It can also be a fixed number whose value is set for flexibility in the configuration file. This is a simple method to optimize a write protected SPICE input netlist circuit with different operating conditions.

- This is optional: no measurements exist in the netlist, although those that will not be used to verify circuit performance and/or correct operation can still be present.

Configuration File

Instructions on how to carry on the optimization are defined in the configuration input file. Information regarding the optimization algorithm schedule, SPICE re-run using the ALTER command, Monte Carlo matching performance, parameters, measurements and post-processing, must be defined in the configuration file which is divided in categories that are now presented.

The following syntax is enforced throughout the configuration file so ASCO can properly write and read the input and output files:

- All comment lines must start with an asterisk (*).

- Comments following a command (in-line) start with the dollar ($) sign.

- Category name is enclosed within the number (#) symbol. If no space exists in the beginning and at the end of the category name (#text#), the command lines in that block of lines cannot be interchanged nor deleted, only the value. On the contrary, if a space is present (# text #), then the category is not locked and an arbitrary number of lines can exist and their relative position is irrelevant.

- Number (#) character at the end of a category must exist at all times.

- Syntax is a colon separated list.

In this category, which is very likely to be revamped in future releases, optimization chain steps are described. So far, only two exist but there is the possibility to make them user defined in the order they are executed and in a fixed number of possible steps.

#Optimization Flow#

Alter:no $do we want to do corner analysis?

MonteCarlo:no $do we want to do MonteCarlo analysis?

AlterMC cost:0.00 $point below which ALTER and/or MONTECARLO can start

ExecuteRF:no $Execute or not the RF module to add RF parasitics?

SomethingElse:

#

Word yes and no are used to perform or not a given analysis in the optimization loop. The scheduled simulations with Alter and/or MonteCarlo, are only executed if all constraints have been met in the previous cost evaluation, otherwise, they are executed immediately after the real value specified in the AlterMC cost.

During and optimization, misconvergence can occur if before starting simulations re-runs using Alter, a lower cost has already been obtained than the possible best when including design corners. This situation can be avoided by not setting AlterMC too low. Similar situation applies to the MonteCarlo case.

Differential Evolution Options

The optimization algorithm settings are grouped in this category which are now explained. Some text has been verbatim copied from the source code.

#DE#

choice of method:3

maximum no. of iterations:50

Output refresh cycle:2

No. of parents NP:60

Constant F:0.85

Crossover factor CR:1

Seed for pseudo random number generator:3

Minimum Cost Variance:1e-6

Cost objectives:10

Cost constraints:100

#

There is no choice of parameters that fits all. Each optimization problem has an ideal choice of the above factors. However F=0.5 and CR=0.8 can be taken as good starting point alongside with method 3 or 4. Read the following lines for further clarification.

- choice of method

An explanation of the naming-convention follows for the DE/x/y/z. DE: stands for Differential Evolution; x: a string which denotes the vector to be perturbed; y: number of difference vectors taken for perturbation of x; z: crossover method (exp = exponential, bin = binomial). When the DE/best... schemes fail DE/rand... usually works and vice versa. One of the following methods can be chosen using a number between 1 and 10.

- DE/best/1/exp: The oldest strategy but still not bad. Several optimization problems where misconvergence occurs have been found.

- DE/rand/1/exp: It works especially well when the “bestit[]”-schemes experience misconvergence. Try e.g. F=0.7 and CR=0.5 as a first guess.

- DE/rand-to-best/1/exp: This strategy seems to be one of the best strategies. Try F=0.85 and CR=1. If you get misconvergence try to increase NP. If this doesn't help you should play around with all three control variables. Similar to DE/rand/1/exp but generally better.

- DE/best/2/exp: Another powerful strategy worth trying.

- DE/rand/2/exp: Seems to be a robust optimizer for many functions.

- DE/best/1/bin: Essentially same strategy but binomial crossover.

- DE/rand/1/bin: Essentially same strategy but binomial crossover.

- DE/rand-to-best/1/bin: Essentially same strategy but binomial crossover.

- DE/best/2/bin: Essentially same strategy but binomial crossover.

- DE/rand/2/bin: Essentially same strategy but binomial crossover.

- maximum no. of iterations NI

Stop criteria. Be aware that the maximum possible number of SPICE simulation calls can be as large as NIxNP. Generations is another name used for iterations.

- Output refresh cycle

- No. of parents NP

Number of population members. To start off NP equal to ten times the number of parameters is a reasonable choice. Increase NP if misconvergence happens. If you increase NP, F usually has to be decreased. The number of population members NP is also not very critical. A good initial guess is 10xD. Depending on the difficulty of the problem NP can be lower than 10xD or must be higher than 10xD to achieve convergence.

- Constant F

DE-stepsize F from interval [0, 2] which affects the differential variation between two individuals. The scale factor F must be above a certain minimum value to avoid premature converge to a local minimum (sub-optimal solution). However, making F too large causes the number of function evaluations to increase before converging to an optimum solution. On the other hand, it allows global exploration of the search space. F is usually between 0.5 and 1 (in rare cases >1). DE is also somewhat sensitive to the choice of the stepsize F.

- Crossover factor CR

Crossover probability constant from interval [0, 1] which affects the diversity of population for the next generation. Helps to maintain the diversity of the population and is rather uncritical, with 0.0, 0.3, 0.7 and 1.0 being optimal first choices. If the parameters are correlated, high values of CR work better. The reverse is true for no correlation. In low-dimensional problems (<10), higher values of crossover probability work better to preserve the diversity in the population.

- seed for pseudo random number generator

Self-explanatory.

- Minimum Cost Variance

Another stop criteria. Simulation stops if current cost variance is smaller than the defined value.

- Cost objectives

in (4.2)

in (4.2)

- Cost constraints

in (4.2)

in (4.2)

More information can be found either in the C source file de36.c or in [SP95,Sto96].

Refer to Section 7.1 for information on this category.

Refer to Section 7.3 for information on this category.

# Parameters #

Supply voltage:#V_SUPPLY#:2.0:0:0:LIN_DOUBLE:---

Supply voltage:#V_SUPPLY#:2.0:0:0:LIN_DOUBLE:OPT

Input frequency:#INP_FREQ#:850E6:0:0:LIN_DOUBLE:---

PMOS width:#WP#:70u:75u:250u:LIN_DOUBLE:OPT

Multiplier:#M#:4:2:5:LIN_INT:OPT

#

A sequence of colon separated specifying different fields: Text description, Symbol, Initial value, Minimum, Maximum, Number format and Type. A clarification of each one the parameters is now presented:

- Text description: of the variable. Any text is acceptable.

- Symbol: must be enclosed with # #. ASCO searches the SPICE input netlist and replaces every single occurrence by its numerical value.

- Initial value: of the parameter.

- Minimum: lower bound of the parameter.

- Maximum: upper bound of the parameter.

- Number format: Naming-convention follows x_y, where x stands for the scale in the feasible range; y is the number format. x can either be LIN (linear interpolation) or LOG (logarithmic interpolation) while y can take DOUBLE (continuous) or INT (discrete) as possible values for the type of variables.

For IEC 60063 preferred number series (E3, E6, E12, E24, E48, E96 and E192 only) use for example :E48: alone. The code was contributed by Stefan Mahr.

- Type: if the parameter is to be optimized, OPT must be added, otherwise use — to represent a parameter that is to be kept constant throughout the optimization. The previous is useful to simulate the exactly same SPICE input netlist under different conditions that are changed only in the configuration file, that is, for netlist integrity purposes.

Notes:

- With the initial value, minimum and maximum, units must not be included, only scale factors. This is: 2A is read as 2 atto instead of 2 Ampere, while 3F is read as 3 femto instead of 3 Farad. The Volt unit (V) must not be added.

- Exponential format (1e2, 1e-5, 1e+4) or engineering format (K, T, N) can be interchangeably used. Use one of the following:

| |

|

T=1E12 |

G=1E9 |

MEG=1E6 |

K=1E3 |

|

|

|

|

|

| A=1E-18 |

F=1E-15 |

P=1E-12 |

N=1E-9 |

U=1E-6 |

M=1E-3 |

|

|

|

|

|

- Character case is ignored.

As such, each one of the above lines implies:

- Supply voltage:#V_SUPPLY#:2.0:0:0:LIN_DOUBLE:—

Text clarifies that this parameter is related to the Supply voltage, the symbol to look for and replace in the SPICE input netlist is #V_SUPPLY#. Initial value used for the optimization is 2.0 Volt with a minimum and maximum of 0. Because it is only a parameter to replace (note the string —) the maximum values would have been ignored. In this case LIN_DOUBLE indicates a parameter with double precision with linear parameter variation.

- Supply voltage:#V_SUPPLY#:2.0:0:0:LIN_DOUBLE:OPT

Owing to the fact that the maximum is equal to the minimum, but the variable is set to optimized, the parallel global DE algorithm is used in an emulated local mode. The minimum and maximum are internally set to -10/+10% of the initial value.

- Input frequency:#INP_FREQ#:850E6:0:0:LIN_DOUBLE:—

The Input frequency where the symbol to look and replace is #INP_FREQ# has an initial value of 850E6 Hertz. Again, because it is not a variable to optimize, due to the presence of —, the minimum and the maximum values are ignored.

- PMOS width:#WP#:70u:75u:250u:LIN_DOUBLE:OPT

The PMOS width has the symbol #WP#. The initial value is 70u. In this case, the parameter is to be optimized (OPT) with a minimum value of 75u and a maximum value of 250u. The double precision is used alongside with a linear swept of the optimization parameter range due to the LIN_DOUBLE keyword.

- Multiplier:#M#:4:2:5:LIN_INT:OPT

Possible values are 2, 3, 4 and 5 for multiplier parameter because xxx_INT is used. Initial value in the optimization is set to 4.

Measurement Options

To avoid the introduction of a user-defined cost function, objectives and constraints must be manually introduced in the configuration input file. As such, measurements that assert circuit performance and/or correct operation shall not be included in the input SPICE netlist (<inputfile>.*). This also simplifies the user work, as the definition of the cost function is frequently tricky. The preferred method is to add an entry in the # Measurements # category of the input configuration file. Furthermore, the added advantage is that this knowledge in the form of objectives and constraints is stored in a template which can be reused later.

# Measurements #

P_SUPPLY:---:MIN:0

P_OUT:OUT:GE:0.0316

#

A sequence of colon separated specifying different fields: Measurement, Node, Objective or Constraint, Gain or Constraint value, having the following meaning:

- Measurement: The name of the measurement to perform. See sub-section 4.3.3 for the format.

- Node: at which the measurement is to be done.

- Objective or Constraint: objectives can either be MIN (minimize) or MAX (maximize) while constraint can be LE (lower-or-equal), GE (greater-or-equal) and EQ (equal: hardcoded to 1 %). MON keyword is used to monitor a measurement while ignoring its value from the cost function calculation.

- Gain or Constraint: value that is dependent on the previous selected parameter. If it is an objective, the entry represents a gain to the cost function (currently not implemented and hardcoded to 10) or else it is the user-defined constraint value.

Taking as example the above lines:

- P_SUPPLY:—:MIN:0

Measure the power supply, no node is specified, minimize is the optimization objective. Because the objective gain is not yet implemented, the hardcoded value of 10 is used instead of 0.

- P_OUT:OUT:GE:0.0316

Measure the output power at node OUT which must be greater-or-equal than 0.0316 Watt.

Only one objective and one constraint is specified, but in theory there is no limit to the maximum number of objectives and/or constraints that can be considered in an optimization. Neither is there a limit to the type of measurements to perform. However, different cost functions or different penalties can lead to distinctive “optimal” solutions. It is thus advisable to have only one objective combined with the necessary constraints. A figure-of-merit (FOM) which accounts for all partial minimize/maximize goals is then minimized by the optimizer.

Post Processing Options

Refer to Section 7.4 for information on this category.

Extract Commands

Each one of the templates is stored in a file in the extract/ directory that must reside in the same parent directory where the SPICE input netlist is. It is mandatory to name the file as the name used in # Measurements # category of the configuration file (Sub-section 4.3.2/Measurement Options).

In EldoTM, the following example is used to measure the output power at a user-defined frequency.

# Info #

Name:P_OUT

Symbol:ZP_OUT

Unit:W

Analysis type:TRAN

Definition:Output power at the fundamental harmonic.

Note:

#

# Commands #

.OPTFOUR TSTART=TMEAS_START TSTOP=TMEAS_STOP NBPT=1024

.FOUR LABEL=fftout v(#NODE#)

.EXTRACT FOUR LABEL=#SYMBOL# {((YVAL(FOUR(fftout), INP_FREQ))^2)/(2*FILT_RES)}

#

# Post Processing #

#

Each file defining one parameter extraction must have the three categories shown above:

- # Info #

All fields are self-explanatory. Currently ignored.

- # Commands #

Commands to be included in the SPICE netlist to extract waveform information from a simulation run are defined here. The node where the measurement is to be done, is replaced by the text given in sub-section 4.3.2/Measurement Options. Currently, the symbol is automatically filled by the tool.

- # Post Processing #

Refer to Section 7.4 for the appropriate syntax. Note, that only the MEASURE_VAR command can be used in here.

The option of naming the output files with the machine name the optimization is running on, is to ease the transition to a multi-CPU environment where multiple machines optimizing the same input SPICE netlist write their output to different files.

All output files are simulator specific and are created by the simulator that is being used. The exception, two log files that report all the steps that have been done during the optimization loop, more precisely:

- <hostname>.log In this file, the results of each one of the simulations is stored in a character separated value for easy importing by a spreadsheet. In each one of the lines a detailed report quantities is given:

- The current cost of the evaluation, which carries the character “+” if all constraints are met, otherwise “-” is added.

- A list of objectives (minimize, maximize), constraints (lower-or-equal, greater-or-equal, equal) and measurements to monitor. Again, those constraints that have been met, have the character “+” added.

- All components values that have been optimized have their value documents on the right most part of each line.

Before exiting, one last simulation is executed with the best set of set of values obtained during the optimization. In this way, it is thus possible to analyze the SPICE output log file and visually see each one of the waveforms for correct operation assurance. The line, or lines in case corner analysis, should start with “+cost”.

- asco.log General information about the optimization process is stored in this file.

Copy the ASCO executable to the directory where your files are. Not obligatory but having everything stored in one place, means that you can move from computer to another, without having to worry if the optimizer is installed or even with different ASCO versions having different formats. Furthermore, by doing this you can easily compare differences between versions. You decide which option best suits your needs.

To invoke ASCO, simply type at the command line:

./asco -<eldo|hspice|ltspice|spectre|qucs|ngspice|general> <inputfile>

The simulator to use must be specified in the first input argument. The <inputfile> can include the file extension.

During a long optimization, which can include corner analysis and/or Monte Carlo simulation, the netlist (<hostname>.tmp) is changed at the beginning of each new step. It might be that everything is running as expected, but the execution of the Alter or Monte Carlo options introduces an error in the temporary file <hostname>.tmp. For this purpose, the executable asco-test is used, since it ignores the fulfillment of any constraint and simple goes from optimization to Alter and then to Monte Carlo.

As programmed, an Alter and/or Monte Carlo simulation is only started after all constraints are met in the previous step. This, unless AlterMC cost is defined in the configuration file with a high value making that the simulation re-runs start immediately, because the returned cost from the previous simulation is lower than the AlterMC cost defined to start simulating the PVT corners. The normal flow, if all steps are to be executed is: optimization Alter

Alter Monte Carlo. If an error exists in any of the subsequent steps, the simulator might not run at all. The necessary corrections must be made so that the sequence of the three steps can end without errors. After this, the long optimization sequence can start, so that at this time one can rest assured that no errors exist in either Alter and/or Monte Carlo netlist. At the command line, type:

Monte Carlo. If an error exists in any of the subsequent steps, the simulator might not run at all. The necessary corrections must be made so that the sequence of the three steps can end without errors. After this, the long optimization sequence can start, so that at this time one can rest assured that no errors exist in either Alter and/or Monte Carlo netlist. At the command line, type:

./asco-test -<eldo|hspice|ltspice|spectre|qucs|ngspice|general> <inputfile>

As programmed in this current version, it is not possible to first execute Monte Carlo simulations and then Alter. Monte Carlo always follows the optimization or Alter.

To provide some help where the execution is going, there are three type of messages that are written to the standard output:

- Informative messages are outputted with INFO: ....

- Debug messages are written with DEBUG: ... and only appear when executing asco-test with the objective to provide enough information to the user to correct the SPICE input netlist and the ASCO configuration file.

- All other remaining messages are error messages. The C code filename and the function at the point the program cannot continue, with a small explanation of the error type is given. The program always exits after this message.

The differential evolution optimization algorithm can be easily parallelized in order to distribute computational effort among different CPUs. This is a consequence of the inherently parallel nature of the DE algorithm within each generation, where population members are individually evaluated. The parallel/distributed version of ASCO can use as many as NP (number of parents in the DE algorithm) computers in parallel because there are no gains in using more.

Interprocess communication is handled by the Message Passing Interface (MPI), a standard for a parallel program on a distributed memory system communicate to other nodes. In the model implemented, there is one master process responsible for giving to each slave the data which is then simulated on another computer. The cost function at the end of each simulation is then returned to the master. Due to the time required for a packet to travel among nodes, and in comparison with the sequential code, the parallel implementation is more suitable to expensive function evaluation.

First it is necessary to download, compile and install the implementation of the MPI standard available at:

http://www.mpich.org/downloads/

If the executable mpicc is not in the PATH environment variable, the ASCO Makefile must be edited and the full path added to CC_MPI. Compile asco-mpi, the executable with parallel processing support by typing at the command prompt:

make asco-mpi

Before continuing, make sure the simulator is available through ssh or rsh. If the PATH environment variable is set in your current shell but not in your remote shell environment, the simulator might not be visible. To test this, type the following at the command line

ssh|rsh <MACHINE_NAME> <simulator>

In case of an error two possible solutions exist. You can either edit your shell configuration file to add the path to the directories that are searched by default, or you can edit the file errfunc.c around line 600-650 (in Step3), and add the full path to the simulator.

To execute the parallel version with just one computer, type

mpirun -np 2 asco-mpi -<simulator> <inputfile>

This is exactly the same as executing the sequential optimization algorithm, but with two processes, one being the master and the other being the slave. Should a network of computers be available, the following method can be used:

mpirun -f machines.txt [-np X] asco-mpi -<simulator> <inputfile>

where, to execute on three computers, machines.txt is a text file containing a list of machines similar to

node1

node1:2 #2 processes on this node

node2:1

node3

in which nodeN is the name of the machine as given by the *NIX command hostname. More than one process can be launched per computer. The simulation netlist(s) and configuration file(s) is/are then copied to the local disk (of the node computer) to reduce traffic in the network and as such decrease total optimization time.

The result given by the parallel version of ASCO is exactly the same as given by the sequential implementation. The exception is in the case where PVT corner analysis is performed. Nevertheless, a similar result is reached.

If the ASCO binary uses all your CPU cycles, you are advised to recompile MPICH using the sock channel instead of the default nemesis channel. You can do this by configuring MPICH with the –with-device=ch3:sock.

asco-mpi with new Spectre versions

versions

If when using asco-mpi with a Spectre simulator version from circa 2012 and onward, the Spectre

simulator version from circa 2012 and onward, the Spectre simulator starts but do not take any CPU, you need to downgrade your MPICH to an older version. New Spectre

simulator starts but do not take any CPU, you need to downgrade your MPICH to an older version. New Spectre simulator versions also use MPI (possibly also MPICH) and it (possibly) interferes with recent MPICH commands. You are advised to use

simulator versions also use MPI (possibly also MPICH) and it (possibly) interferes with recent MPICH commands. You are advised to use

http://ftp.mcs.anl.gov/pub/mpi/mpich-1.2.7p1.tar.gz

In itself, the ASCO tool does not define the accuracy of the results. The algorithm used in ASCO has been applied to various sets of problems and has obtained good results in term of speed, robustness and convergence. More information is available in the DE's homepage in: http://www.icsi.berkeley.edu/ storn/code.html.

storn/code.html.

The methodology applied to the ASCO tool has been proved on silicon. For further details see Chapter 2 [Ram05] for a low-voltage low-power design of a three stage operational amplifier and Chapter 6 [Ram05] for the design in the presence of passive and board parasitics, a high-efficiency 30 dBm class-E CMOS two-stage power amplifier for the GSM standard.

In the DE algorithm, alongside with the choice of method, three parameters deserve special attention to define the convergence speed: NP, F and CR. Electric circuits transfer function being multi-modal require large populations (NP) to find a working topology. Likewise, the constant F must be above a certain value so that premature convergence to a local minimum does not occur. In addition to that, parameters are usually dependent which makes large values of CR work better. However, overestimating NP and F has the consequence that the number of SPICE simulation calls grow quickly, and thus, slows the optimization process.

A careful selection of the number of optimization PVT corners and a thoughtful number of Monte Carlo simulations, is a good trade-off between optimization time and robustness. In addition, planning the exact moment to start sweeping the process corners is critical for minimizing CPU time. A two-step approach, where first only the optimization is done, followed by shrinking the variables search space to the range where all constraints have been met, i.e., upper and lower range from all the lines starting with +cost. Only then, the more computer intensive PVT optimization is performed.

Minimizing the number of ASCII and binary files created by the simulator, the number of measurements (.EXTRACT or .MEAS) and output variables (.PROBE), and the number of analysis (.AC, .PZ and .TRAN) to the absolute minimum required to efficiently characterize the circuit in conjunction with a keen speed/accuracy simulation compromise, saves precious CPU time in the optimization loop.

Open literature suggests that further gains in terms of convergence speed could be obtained by first doing a global search to find a good starting point that is latter used by a local optimization algorithm such as Hooke&Jeeves or Nelder-Mead. This decision is taken at compilation time by editing the file asco.c around Step4.

Fully optimizing from scratch a complex system with a considerable number of variables might end up being a road block, although being possible to do by the tool. In same cases, it may be more efficient to steadily increase the number of variables to optimize and learn from experience. Furthermore, overly increasing the search space with the hope of finding the very best solution, might once more lead to an endless optimization loop.

Too many objectives and/or constraints may require a circuit that is simply not feasible in theory. A reduced number is advisable whenever wanting to explore a new operating point that is simply too difficult to derive equations for. Yet, in same situations a given constraint is paramount to guide the optimizer to a functional solution that otherwise is difficult to reach. Experience is once more an added value.

Whenever possible, try to understand the reasons behind the optimization results. Always proceed with caution unless you can justify the proposed circuit sizes. To increase confidence, re-run the simulation with the Alter option enabled and/or with a different range of the search space for the optimization variables. If a similar result is obtained, the optimizer is probably converging to the global minimum and the circuit is likely working as desired. In this situation in asco.log, the cost-variance is « 1.

Thoroughly analyze the asco.log file as the circuit can be working on an undesired operating point or on the edge of stability. Then, explain what the optimizer has found.

ASCO Tutorials

This chapter contains a description of examples included with the ASCO tool which are grouped by simulator name (Table 6.1). The basic step to prepare a new netlist to the format compatible with the ASCO optimization tool involves:

- <inputfile>.*

- Prepare a functional SPICE netlist for your simulator.

- Measurement commands that are used to assert circuit performance and/or correct operation are (preferably) not included in the input SPICE netlist.

- Select the variables to optimize. Replace their value with a unique string and enclose it in # #.

- <inputfile>.cfg

- Edit the configuration file. Pay special attention to the category # Parameters # and # Measurements # in which the symbol and measurement name must match those in file <inputfile>.* and directory extract/, respectively.

- Adapt the three DE control parameters: NP, F and CR, according to the difficulty of the optimization problem.

- Carefully review if the remaining configuration file suits your needs.

- Create the necessary measurements, each one in a separate file and place them in the directory extract/ which is in the same parent directory where the SPICE input netlist is. If available from a central repository or another simulation, simply copy the necessary files.

- Run the asco-test executable to remove any existing error. Only then proceed with the following steps.

- Copy the ASCO executable to the place where your SPICE file is. Start the optimization loop.

- During the optimization loop, data similar to the one below is printed to the terminal,

asco-0.4.1 - Copyright (c) 1999-2006 Joao Ramos

This program is distributed in the hope that it will be useful,

but WITHOUT ANY WARRANTY; without even the implied warranty of

MERCHANTABILITY or FITNESS FOR A PARTICULAR PURPOSE. See the

GNU General Public License for more details.

INFO: Current directory on 'linux': /home/users/asco/examples/inv

INFO: Eldo initialization on 'linux'

INFO: Initialization has finished without errors on 'linux'

PRESS CTRL-C TO ABORT

INFO: Starting global optimizer on 'linux'...

PRESS CTRL-C TO ABORT

Best-so-far cost funct. value=1.6891

best[0]=-4.180591714

best[1]=6.665600201

best[2]=0.03964113694

best[3]=-7.372717493

best[4]=3.691704024

Generation=1 NFEs=80 Strategy: DE/rand-to-best/1/exp

NP=40 F=0.7 CR=0.9 cost-variance=8.2357e+12

which is a summary of the optimization startup procedure. No errors have occurred during the initialization of the optimization which has 5 optimization variables. The values of best[], always between -10 and +10, are the values proposed by the DE algorithm. They are later scaled to the range defined in <inputfile>.cfg.

- Upon ending the optimization, text similar to the next is printed in the terminal showing the final optimization results.

Best-so-far cost funct. value=0.40609

best[0]=-5.173398086

best[1]=9.592135291

best[2]=9.780050221

best[3]=-8.086606726

best[4]=9.822119525

Generation=51 NFEs=2080 Strategy: DE/rand-to-best/1/exp

NP=40 F=0.7 CR=0.9 cost-variance=0.026777

INFO: de36.c - Maximum number of generations reached (genmax=50)

Ending optimization

INFO: ASCO has ended on 'linux'.

The cause for the optimization ending is also printed, in this case the maximum number of generations has been reached. The minimum obtained cost of 0.40609 is achieved after 50 generations and 2080 function evaluations. The optimization has converged as result of the low value of the cost-variance. Although this may be true, some of the best[] are close to the search range of [-10, +10]. This can be the result that toward the minimum and/or maximum value of a given vector lies the optimum point. Therefore it is advisable to increase the lower bound for best[] vectors close to -10 and the upper bond for best[] vectors close to +10.

- Analyze the results stored in asco.log, <hostname>.log and the other simulator specific output files. If not already created (to increase optimization speed), re-run one last simulation with the necessary command(s) to save waveforms in an appropriated binary format suitable for a graphical viewer.

The following ready to use optimization examples can be found in the directory examples/ of the ASCO distribution, grouped for each one of the supported simulators.

Table 6.1:

ASCO Examples

| Circuit Name |

Description |

|

|

| inv |

Digital inverter |

|

|

| amp3 |

Three stage operational amplifier |

|

|

| classE |

Class-E power amplifier |

|

|

| bandpass |

Chebyshev band pass filter |

|

|

Up to 2008.

This simple circuit gives a quick introduction to the procedures that must be executed before optimizing a circuit. The complete set of files described below can be found in examples/Eldo/inv.

The fact is that circuits having only one variable makes convergence quite fast on modern computers. As such, an example will show most of the ASCO present capabilities: optimize from scratch a circuit to achieve minimum power consumption while fulfilling the design constraints; guarantee that this is valid for different process corners and also take into account device parameter mismatch (Monte Carlo).

Figure 6.1:

Digital inverter.

|

- One optimization variable

- One objective

- Two constraints/performance goals

- Three design corners (ALTER)

- Monte Carlo analysis

*Digital inverter

.PARAM V_SUPPLY = '#V_SUPPLY#'

.PARAM INP_FREQ = '#INP_FREQ#'

.PARAM INP_PERIOD = '1/INP_FREQ'

.PARAM NO_PERIODS = '4'

.PARAM TMEAS_START = '(NO_PERIODS-1)*INP_PERIOD'

.PARAM TMEAS_STOP = '(NO_PERIODS)*INP_PERIOD'

.PARAM TMEAS_1 = 'TMEAS_STOP -3*INP_PERIOD/4'

.PARAM TMEAS_2 = 'TMEAS_STOP -1*INP_PERIOD/4'

*** *** SUPPLY VOLTAGES *** ***

VDD VDD 0 V_SUPPLY

VSS VSS 0 0

*** *** INPUT SIGNAL *** ***

VSIG IN VSS PULSE V_SUPPLY 0 'INP_PERIOD/2' 'INP_PERIOD/1000'

+ 'INP_PERIOD/1000' 'INP_PERIOD/2' 'INP_PERIOD'

*** *** CIRCUIT *** ***

MP OUT IN VDD VDD PMOS W='#WP#' L=#LMIN#

MN OUT IN VSS VSS NMOS W='#WP#/3' L=#LMIN#

CL OUT VSS 10p

*** *** ANALYSIS *** ***

.TRAN 'INP_PERIOD/1000' 'NO_PERIODS*INP_PERIOD'

.MC 2 ALL

.PROBE TRAN V(IN)

.PROBE TRAN V(OUT)

.OPTION EPS=1E-6

.INCLUDE p.typ

.INCLUDE n.typ

.END

The CMOS inverter, in which the transistor width is to be optimized has a 10 pF load capacitance. All measurements have been removed from the netlist and included in the extract/ directory.

From the complete configuration file, available at /examples/Eldo/inv, only those categories that might require extra attention are now discussed.

#Optimization Flow#

Alter:yes $do we want to do corner analysis?

MonteCarlo:yes $do we want to do MonteCarlo analysis?

AlterMC cost:3.00 $point at which we want to start ALTER and/or MONTECARLO

ExecuteRF:no $Execute or no the RF module to add RF parasitics?

SomethingElse: $

#

Simulation re-runs are executed immediately upon having a returned cost below 3.00. Immediately after that, and because the AlterMC cost is smaller than the returned cost from the simulation, Monte Carlo Simulation is performed. For this to occur, the line .MC 2 ALL has to be present which tells the number of simulations runs, also ALL must exist.

# ALTER #

.param

+ V_SUPPLY=[2.0 2.1 2.2]

#

As a demonstration, only three process corners are executed. For an extensive list of possible examples refer to the configuration file.

# Parameters #

Supply voltage:#V_SUPPLY#:2.0:0:0:LIN_DOUBLE:---

Temperature:#TEMP#:25:0:0:LIN_DOUBLE:---

Minimal gate length:#LMIN#:0.35u:0:0:LIN_DOUBLE:---

Input frequency:#INP_FREQ#:850E6:0:0:LIN_DOUBLE:---

PMOS width:#WP#:10000u:1m:10m:LIN_DOUBLE:OPT

#

The PMOS transistor width is the only optimization variable used. The other parameters are used to configure the SPICE input netlist.

# Measurements #

P_SUPPLY:---:MIN:0

VHIGH:OUT:GE:1.95

VLOW:OUT:LE:0.05

#

In here, minimization of the power supply consumption is the objective. This, while meeting the constraint of having an output voltage above 1.95 V and below 0.05 V at a fourth of the signal period.

./asco -eldo inv

An inverter is a rather simple circuit. It can however be used as a good starting point on the steps required to check that not only the optimization has converged, but above all, to confirm that the circuit is indeed working according to the initial constraint and in a stable operating mode.

To verify that the optimization leads to a functional inverter, the binary output file containing the simulation with the best set of values obtained during the optimization is checked with the visual display of the saved output.

In the <hostname>.log file, a complete report of all simulations is stored. The last 12 lines refer to the bet test vector (Alter plus Monte Carlo). It is possible that not all lines start with “+cost”. It should nevertheless be noted that the measured values are indeed very close to the constraint values. The number of function evaluations, minimum cost and cost-variance are stored in asco.log file. The reason for ending the optimization and a brief report of the DE parameters is stored in here for convenience.

The most important place to check correct operation is in the SPICE output log file: <hostname>.chi. A meticulous analysis is mandatory.

In the event that there is a need for statistical analysis on the simulation output log file, the tool log available in tools/log/ can be used. It takes as input the optimization log file and creates a summary of all performed measurements. Should the <inputfile>.cfg exist, a more complete report is created. To use such tool, type in the command prompt

<PATH_TO_LOG>/log <hostname>.log <hostname>.log.log

to obtain a file with a summary of the measurements and also with a list of parameters to use in new optimization. However, it is better to create the new parameter list (# Parameters #) in the situation where all constraints have been met, i.e., those where the line start with +cost. Filtering lines matching a pattern is obtained using the *NIX grep command

cat <hostname>.log | grep +cost > <hostname>_good.log

<PATH_TO_LOG>/log <hostname>_good.log <hostname>_good.log.log

after which a new summary can be obtained, this time with a smaller range for the parameters. With this in hand, a new re-run can be started, either to fine-tune the design or for a new and faster optimization having corners.

This tutorial describes the optimization of a three stage operation amplifier featuring the frequency compensation technique described in [Ram05]. The necessary files are available in examples/Eldo/amp3.

Figure 6.2:

The PFC amplifier [Ram05].

[Block diagram of the PFC amplifier.] ![\includegraphics[width=0.50\columnwidth]{figures/PFCBlockDiagram}](img36.png) [Schematic diagram of the PFC amplifier.]

[Schematic diagram of the PFC amplifier.] ![\includegraphics[width=0.50\columnwidth]{figures/PFCSchematic}](img37.png) |

- 21 optimization variables

- One objective

- Five constraints/performance goals

*Three stage operational amplifier

*** *** OPAMP SUBCIRCUIT *** ***

.SUBCKT PFC.SUB VP VN VOUT IBIAS VB1 AVDD AVSS

M00 IBIAS IBIAS AVDD AVDD PMOS W=#WM00_10# L=#LM1#

* differential pair

M10 1 IBIAS AVDD AVDD PMOS W=#WM00_10# L=#LM1# M=6

M11 2 VN 1 1 PMOS W=#WM11_12# L=#LM2#

M12 3 VP 1 1 PMOS W=#WM11_12# L=#LM2#

* folded cascode

M13 4 IBIAS AVDD AVDD PMOS W=#WM13_16# L=#LM1# M=3

M16 5 IBIAS AVDD AVDD PMOS W=#WM13_16# L=#LM1# M=3

M14 4 VB1 2 AVSS NMOS W=#WM14_17# L=#LM3#

M17 5 VB1 3 AVSS NMOS W=#WM14_17# L=#LM3#

M15 2 4 AVSS AVSS NMOS W=#WM15_18# L=#LM4#

M18 3 4 AVSS AVSS NMOS W=#WM15_18# L=#LM4#

* second stage

M20 6 5 AVDD AVDD PMOS W=#WM20# L=#LM6#

M22 7 IBIAS AVDD AVDD PMOS W=#WM22# L=#LM1#

M21 6 6 AVSS AVSS NMOS W=#WM21_23# L=#LM5#

M23 7 6 AVSS AVSS NMOS W=#WM21_23# L=#LM5#

* third stage

M30 VOUT 5 AVDD AVDD PMOS W=#WM30# L=#LM6# M=22

M31 VOUT 7 AVSS AVSS NMOS W=#WM31# L=#LM7# M=5

* compensation

CM1 5 VOUT #CC1#

CM2 5 7 #CC2#

.ENDS PFC.SUB

*** *** SUPPLY VOLTAGES *** ***

VDD VDD 0 #VSUPPLY#

VSS VSS 0 0

*** *** BIAS VOLTAGE *** ***

VVB1 VB1 VSS DC #VBIAS#

*** *** BIAS CURRENT *** ***

IIBIAS IBIAS VSS #IBIAS#

*** *** SUB-CIRCUIT *** ***

XOPAMP VP VN VOUT IBIAS VB1 VDD VSS PFC.SUB

*** *** LOAD *** ***

RL VOUT VX #RLOAD#

CL VOUT VX #CLOAD#

VX VX VSS '#VSUPPLY#/2'

*** *** AC LOOP *** ***

VIN VP VSS '#VSUPPLY#/2' AC 1

RX VN VOUT 1m AC=1E12

CX VN VSS 10

*** *** ANALYSIS *** ***

.AC DEC 100 0.001 1E9

.PZ V(VOUT)

.PROBE AC VDB(VOUT)

.PROBE AC VP(VOUT)

.OP

.OPTION NOBOUND_PHASE

.INCLUDE p.typ

.INCLUDE n.typ

.END

#DE#

choice of method:3

maximum no. of iterations:100

Output refresh cycle:2

No. of parents NP:100

Constant F:0.7

Crossover factor CR:0.9

Seed for pseudo random number generator:3

Minimum Cost Variance:1e-6

Cost objectives:10

Cost constraints:10e6

#

A random starting point is used in combination with a population size of 100 for the evolutionary optimization algorithm. The number of iterations is arbitrarily set to 100, which translates into a long optimization time. However, this allows to verify that the optimal values are no longer changing significantly.

# Parameters #

Supply voltage:#VSUPPLY#:3.0:2.4:3.3:LIN_DOUBLE:---

Minimal gate length:#LMIN#:0.35U:0.35U:0.35U:LIN_DOUBLE:---

Bias voltage:#VBIAS#:1.25:1:3.0:LIN_DOUBLE:OPT

Bias current:#IBIAS#:5E-6:1E-6:10E-6:LIN_DOUBLE:OPT

Load capacitance:#CLOAD#:100E-12:100E-12:130E-12:LIN_DOUBLE:---

Load resistance:#RLOAD#:25E3:10E3:50E3:LIN_DOUBLE:---

C compensation 1:#CC1#:15p:2p:20p:LIN_DOUBLE:OPT

C compensation 2:#CC2#:3p:2p:20p:LIN_DOUBLE:OPT

Length group 1:#LM1#:0.7E-6:0.35E-6:7E-6:LIN_DOUBLE:OPT

Length group 2:#LM2#:0.7E-6:0.35E-6:7E-6:LIN_DOUBLE:OPT

Length group 3:#LM3#:0.7E-6:0.35E-6:7E-6:LIN_DOUBLE:OPT

Length group 4:#LM4#:0.7E-6:0.35E-6:7E-6:LIN_DOUBLE:OPT

Length group 5:#LM5#:0.7E-6:0.35E-6:7E-6:LIN_DOUBLE:OPT

Length group 6:#LM6#:0.7E-6:0.35E-6:7E-6:LIN_DOUBLE:OPT

Length group 7:#LM7#:0.5E-6:0.35E-6:7E-6:LIN_DOUBLE:OPT

Width M00_10:#WM00_10#:10E-6:0.35E-6:50E-6:LIN_DOUBLE:OPT

Width M11_12:#WM11_12#:40E-6:0.35E-6:50E-6:LIN_DOUBLE:OPT

Width M13+16:#WM13_16#:10E-6:0.35E-6:50E-6:LIN_DOUBLE:OPT

Width M14_17:#WM14_17#:6E-6:0.35E-6:50E-6:LIN_DOUBLE:OPT

Width M15_18:#WM15_18#:11.01E-6:0.35E-6:50E-6:LIN_DOUBLE:OPT

Width M20:#WM20#:15E-6:0.35E-6:50E-6:LIN_DOUBLE:OPT

Width M22:#WM22#:10E-6:0.35E-6:50E-6:LIN_DOUBLE:OPT

Width M21_23:#WM21_23#:2E-6:0.35E-6:50E-6:LIN_DOUBLE:OPT

Width M30:#WM30#:1.5E-6:0.35E-6:50E-6:LIN_DOUBLE:OPT

Width M31:#WM31#:1.5E-6:0.35E-6:50E-6:LIN_DOUBLE:OPT

#

In order to automatically size the amplifier circuit, the netlist of the PFC amplifier is parametrized using 21 design variables (one bias voltage and current, two compensation capacitors, seven transistor lengths and ten transistor widths). The number of transistor geometry variables is somewhat reduced by taking standard analog design constraints (e.g. the matching of differential input pairs and current mirrors) into account. However, constraints on the operating point of the circuit are not included, only the performance specifications are given as input to the tool. On the one hand, this makes the design space much more complex, but on the other hand this doesn't require specific circuit knowledge.

# Measurements #

ac_power:VDD:MIN:0

dc_gain:VOUT:GE:122

unity_gain_frequency:VOUT:GE:3.15E6

phase_margin:VOUT:GE:51.8

phase_margin:VOUT:LE:70

amp3_slew_rate:VOUT:GE:0.777E6

#

The original performances as in [Ram05] are taken as constraints, except for the power consumption, which is requested to be minimized.

./asco -eldo amp3

Depending on the computer speed, it may take between 10 and 30 minutes to find the first circuit that fulfills all design constraints. By comparison, the full optimization procedure takes much more time. To have a cost-variance « 1 it is necessary to increase the maximum number of iterations to about 400. Although this optimization can be done in a single day, a somehow simpler yet accurate representation of the amplifier as depicted in Fig. 6.2(a) can be used. After obtaining the optimum values for the transconductances and compensation capacitors in a fraction of the time, proceeding to the optimization of the transistor level circuit in Fig. 6.2(b) is straightforward.

In this example, a simple class-E amplifier intended for operation in the GSM-850 band is given. A more realistic model representing a differential two stage power amplifier, including all relevant circuit and board parasitics to better describe the circuit measurement performance alongside with measurements from a manufactured chip in a 0.35 um CMOS commercial technology, is given in [Ram05]. All the files are available at examples/Eldo/classE.

Figure 6.3:

Class E power amplifier. It consists of CMOS switch  , the finite dc-feed inductance

, the finite dc-feed inductance  , the series-tuned (

, the series-tuned ( -

- ) and the load resistance

) and the load resistance  .

.

|

- Five optimization variables

- One objective

- Five constraints/performance goals

*Class-E power amplifier

.PARAM V_SUPPLY = '#V_SUPPLY#'

.PARAM INP_FREQ = '#INP_FREQ#'

.PARAM INP_PERIOD = '1/INP_FREQ'

.PARAM NO_PERIODS = '#NO_PERIODS#'

.PARAM TMEAS_START = '(NO_PERIODS-1)*INP_PERIOD'

.PARAM TMEAS_STOP = '(NO_PERIODS)*INP_PERIOD'

.PARAM T_PERC = 99

.PARAM TMEAS_AUX = (NO_PERIODS-1)*INP_PERIOD

+ + T_PERC/100*INP_PERIOD

*** *** SUPPLY VOLTAGES *** ***

* Voltages and currents

VDD VDD 0 V_SUPPLY

VSS VSS 0 0

*** *** INPUT SIGNAL *** ***

VSIG G1 VSS PULSE V_SUPPLY 0 'INP_PERIOD/2' 'INP_PERIOD/1000'

+ 'INP_PERIOD/1000' 'INP_PERIOD/2' 'INP_PERIOD'

*** *** INDUCTOR *** ***

.SUBCKT LBOND.SUB IN OUT L=1

RBOND IN 1 '0.135*(L/1n)' ! 0.135 Ohm/mm; gold

LBOND 1 OUT 'L' ! 1 nH/mm

.ENDS LBOND.SUB

*** *** OUTPUT STAGE *** ***

* Diffusion length, MOSwidth, MOSlength and multiplier

.PARAM LDIFF='1.2u' WS='#TR1_W#' LS='#LMIN#' MS='1'

M1 D1 G1 VSS VSS NMOS W=WS L=LS M=MS AD='WS*LDIFF' PD='2*(LDIFF+WS)'

+ AS='WS*LDIFF' PS='2*(LDIFF+WS)'

XL1 VDD D1 LBOND.SUB L=#L1#

XL0 D1 N2 LBOND.SUB L=#L0#

C0 N2 OUT #C0#

.PARAM FILT_RES = #RL#

R OUT VSS FILT_RES

*** *** ANALYSIS *** ***

.TRAN 'INP_PERIOD/1000' 'NO_PERIODS*INP_PERIOD'

.PROBE TRAN V(G1)

.PROBE TRAN V(D1)

.PROBE TRAN V(OUT)

.OP

.OPTION EPS=1E-6

.INCLUDE n.typ

.END

The above file represents a class-E amplifier with a NMOS transistor acting as a switching device. Minimum inductor parasitics, using SPICE language, are included by the fact of the LBOND.SUB sub-circuit.

The relevant code from the configuration is now shown:

# DE #

choice of method:3

maximum no. of iterations:50

Output refresh cycle:2

No. of parents NP:60

Constant F:0.85

Crossover factor CR:1

Seed for pseudo random number generator:3

Minimum Cost Variance:1e-6

Cost objectives:10

Cost constraints:100

#

The three control parameters controlling the optimization algorithm and that must be chosen by the user: NP, F and CR are set to 60, 0.85 and 1, respectively.

# Parameters #

Supply voltage:#V_SUPPLY#:2.0:0:0:LIN_DOUBLE:---

Temperature:#TEMP#:25:0:0:LIN_DOUBLE:---

Minimal gate length:#LMIN#:0.35u:0:0:LIN_DOUBLE:---

Input frequency:#INP_FREQ#:850E6:0:0:LIN_DOUBLE:---

No of sim periods:#NO_PERIODS#:50:0:0:LIN_DOUBLE:---

TR1 width:#TR1_W#:1600.0u:5000u:20000u:LIN_DOUBLE:OPT

L1 inductance:#L1#:38.2n:0.1n:10n:LIN_DOUBLE:OPT

L0 inductance:#L0#:14.4n:0.1n:10n:LIN_DOUBLE:OPT

C0 capacitance:#C0#:4.82p:10p:70p:LIN_DOUBLE:OPT

Load resistance:#RL#:27.9:1:10:LIN_DOUBLE:OPT

#

In first three lines above, inputs for the SPICE simulation are shown. The next five lines configure the parameters to be optimized with the bounding range for each one of the circuit components.

# Measurements #

P_SUPPLY:---:MIN:0

P_OUT:OUT:GE:0.5

VDSOFF:D1:LE:0.2

SLOPEOFF:D1:LE:9E9

VDSON:D1:LE:0.2

VMIN:D1:GE:-0.2

#

The above category describes minimization of the power supply (the only objective) while meeting all other five constraints, specifically an output power of at least 0.5 W. The remaining four performance goals, ensure correct operation of the circuit as a class-E amplifier.

The minimization of the power supply while constraining the output power to be higher than 0.5 W is equivalent to maximizing the drain efficiency, thus the cost function has only one objective.

./asco -eldo classE

Upon completion, all simulator calls are logged to <hostname>.log. Each one of the lines contains the cost of the simulation, the power supply and a description of all performance goals which have the character "+" added if the constrain has been met, otherwise, have "-". The last part of the line have a list of all circuit sizes used in the simulation.

The character separated value makes importing to a spreadsheet easy where performance trade-offs among the various optimized circuit solutions can be studied: results in which the DC-feed inductance (L1) is below a certain threshold although the output power is less than the desired 0.5 W; all the cases where when transistor turns on, the voltage across the transistor drain is below than 0.2 V; etc. However, for situations where all constraints must strictly be met, the simple following shell command can be typed in the command prompt, to filter only those solution that have met all performance goals.

cat <hostname>.log | grep +cost > good.log

The same spreadsheet can again be used to analyze all results resting

assured that only those where the design constraint have been met are shown.

Existing passives, either discrete or integrated have parasitics that must be considered when doing a design at high-frequency. Yet, accounting for their effect is often tedious and time consuming. As such, it becomes increasingly difficult to generate equations that are adequately accurate.

The RF module described in Section 7.5 can be used for situations when is of paramount importance to consider parasitic effects in a circuit. To this end, the circuit can have the necessary devices to describe a real world implementation, including chip, packaging and board parasitics. Considering them during the optimization, leads to a closer match between simulations and lab measurements. All the files are available at examples/Eldo/bandpass.

Figure 6.4:

The Chebyshev band pass filter.

[Magnitude constraints tolerance scheme.] ![\includegraphics[width=0.45\columnwidth]{figures/BPConstraints}](img39.png)

[Circuit topology.] ![\includegraphics[width=0.45\columnwidth]{figures/BPTopology}](img40.png)

[Equivalent of (b) with parasitics automatically added by the RF module during the optimization loop.] ![\includegraphics[width=0.45\columnwidth]{figures/BPTopologyFullParasitics}](img41.png)

|

- Six optimization variables

- One objective

- Three constraints/performance goals

*Chebyshev Band Pass Filter

*** *** FILTER CIRCUIT *** ***

C1 1 0 #C1# ! #CSMD_50p80p#

L1 1 0 #L1# ! #LBOND_350p450p#

L2 1 2 #L2# ! #LBOND_60n100n#

C2 2 3 #C2# ! #CSMD_300f340f#

C3 3 0 #C3# ! #CSMD_50p80p#

L3 3 0 #L3# ! #LBOND_350p450p#

*** *** PORT *** ***

V1 1 0 iport=1 rport=50

V2 3 0 iport=2 rport=50

*** *** ANALYSIS *** ***

.AC DEC 1000 800e6 1200E6

.PROBE AC SDB(1,1)

.PROBE AC SDB(2,1)

.END

The above text, describes a three pole Chebyshev band pass filter. The user-defined device models, are specified after the in-line comment specific to each one of the simulators used. Refer to Section 7.5 for a detailed description of its usage.

The relevant code from the configuration file is now shown:

#Optimization Flow#

Alter:no $do we want to do corner analysis?

MonteCarlo:no $do we want to do MonteCarlo analysis?

AlterMC cost:1.00 $point at which we want to start ALTER and/or MONTECARLO

ExecuteRF:yes $Execute or no the RF module to add RF parasitics?

SomethingElse:

#

The difference to note is the definition of ExecuteRF setting to require the inclusion of RF parasitics in the netlist.

#DE#

choice of method:3

maximum no. of iterations:100

Output refresh cycle:2

No. of parents NP:30

Constant F:0.7

Crossover factor CR:0.9

Seed for pseudo random number generator:3

Minimum Cost Variance:1e-6

Cost objectives:10

Cost constraints:1000

#

Above, normal settings for an optimization. Increase the number of parents to achieve better results at the expense of a longer simulation time.

# Parameters #

C1:#C1#: 64.415p: 50p: 80p:LIN_DOUBLE:OPT

L1:#L1#: 393.233p:350p:450p:LIN_DOUBLE:OPT

L2:#L2#: 79.107n: 60n:100n:LIN_DOUBLE:OPT